Select your machine

CryoHeat Metal Treatment & Micropolishing

Many of the UTV Industry's elite racers, including Matt Burroughs (Can-Am Maverick X3), Wayne Matlock (Polars RZR XP Turbo) and Dustin Nelson (Yamaha YXZ 1000R) all swear by the magical power of CyroHeat. But, what is it? And, why should even the "Weekend Warrior" consider it for their High Performance UTV? We connected with the owner of CryoHeat, Josh Lahaye, to break down his Metal Treatment & Micropolishing process.

Read More UTVDRIVERCryoheat Treated

Read what our customers have to say!

"First thing is.......the bike puts out an incredible amount of power. I would love to put it on a dyno and see what numbers it gets but dont really feel like spending a couple hundred bucks to do it. Jack has his hands full keeping the front wheel from wanting to come up on him.

Through all the regionals and racing at Lorettas the bike ran incredibly well. I put it together with a 2 ring piston that was Cryoheat treated but switched to a single ring before Lorettas that was not treated. Josh said that the cryoheat treatment would extend service life and now I believe him. My usual piston change timeline has been between 20 to 25 hours. I always measure ring gap clearances when I put it together and when I take it apart. The piston I took out right before Lorettas had about 18 hours on it. A non treated piston would show a ring gap change in the range of .005 to .008. This Treated piston only showed a change of .001 after the 18 hours.

Jack spent the month of July leading up to Lorettas training in North Carolina at the Bennick compound with Daxton Bennick, Hayden Deegan, and a few other national champions. He grew a lot as a rider and as a man. He had to take care of his bikes, do his laundry and cook all his own meals.

You can see him in a lot of the Deegan38 YouTube videos during July. This one from Lorettas shows his Moto 1 start and what a challenge it was to keep the front of the bike planted. His start is at about 1:20"

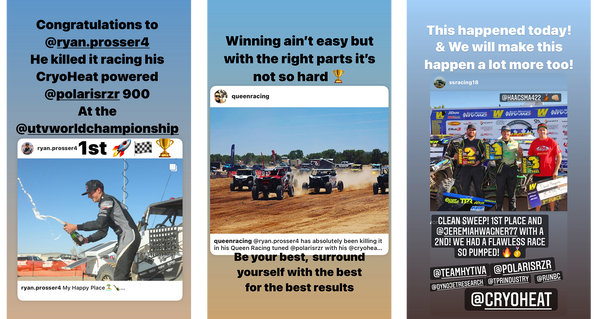

CryoHeat’s involvement in the UTV/SXS industry began in 2012. Local racers and UTV enthusiasts quickly saw huge results with CryoHeat processed CV Joints. CryoHeat soon took on factory Yamaha sponsored Dustin Nelson and his Yamaha YXZ 1000 in the Worcs Series and Lucas Off Road Series. Thanks to CryoHeat, the greatly enhanced metal of his complete power train helped him overcome DNFs and enabled him to win more races and championships than ever. In 2016 Dustin won over 16 professional races and 2 championships in short course racing. That was just the beginning of his winning streak.

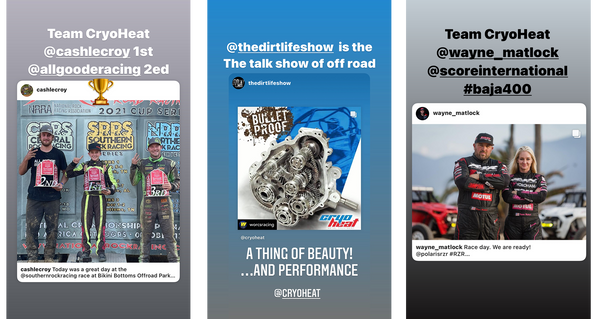

In 2015 CryoHeat took on another professional UTV/SXS Racer Wayne Matlock, racing Score International starting off with the 2015 Baja 500. Almost every part of Matlocks Polaris RZR XP1000 was CryoHeat treated and Micropolished – he finished first place with over a 1.5 hour lead and then he also took first place in the 2015 Baja 1000. In 2016, Matlock dominated the Baja 500 again; this put CryoHeat on the map as being a successful business in the UTV industry and a leader in cutting edge technology.

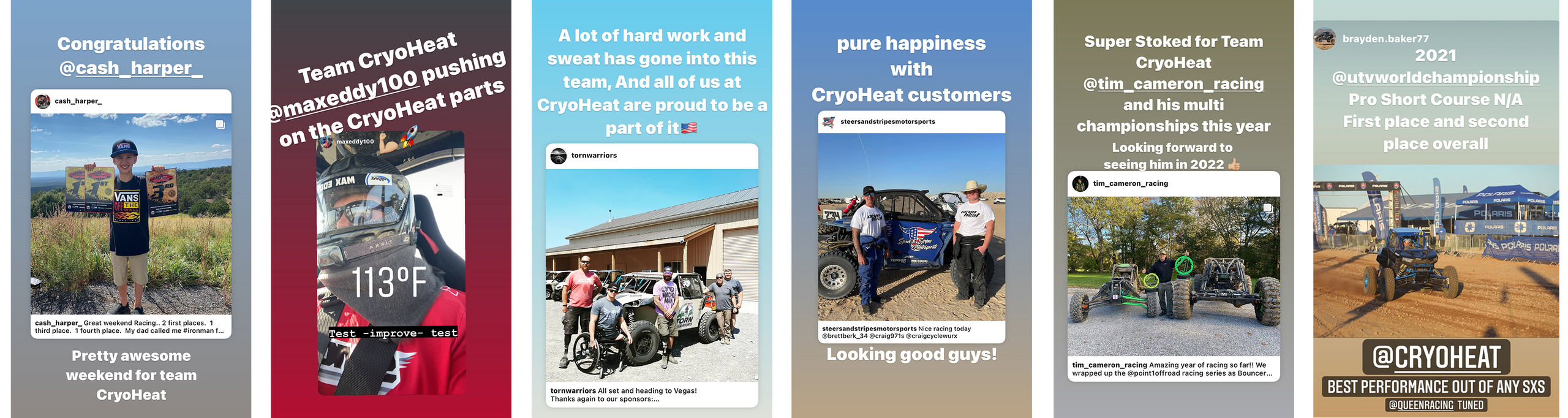

Today team CryoHeat works with many professional athletes racing UTV/SXS in short course, Desert, rally, mud bounty holes, Hill shooters, drag racing and in the rocks. Team CryoHeat has won many championships and races in Score International, Best In The Desert BITD, King Of Hammers, WORCS, Midamerica Outdoors, Pro Rock Racing, Tex Plex Park, The Mint 400, Southern Rock Racing SRRS, Central Rock Racing CRRS, Northern Rock Racing NRRD, Ultra4 Racing, DP4 Racing, SNORE, AMA District 37, AMA District 38 and many more.

Currently in 2022 Team CryoHeat has treated and built more than 6000 CV Joints, hundreds of axles, over 4000 UTV/SXS transmissions, differentials and almost 100 engines. In 2020 CryoHeat got heavy into manufacturing parts for the Polaris RZR, Can-Am X3 and the Honda Talon.

SPONSORED RACERS

For more information on CryoHeat Sponsorships, and CryoHeat Sponsored services:[Lahaye/CryoHeat 2025 SPONSOR DECK]

VIEW SPONSOR DECK

MAX EDDY JR. #57

Desert Racer

RYAN PROSSER #944, #1944

Short Course

SHAWN SAXTON #18

Short Course

CASH LeCROY #6, #9, #27

Rock Bouncer/Hill Climber/Short Course

MARC BURNETT #2905

Desert Racer

JP ALVAREZ #192

TRISTAN ALVAREZ #114

JOSHUA LAHAYE #219