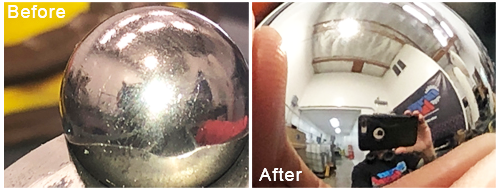

The CryoHeat Micropolishing consists of rotating a part at relatively slow speeds. As the part rotates through the machine, our proprietary non-abrasive media makes contact on all surfaces of the part. At CryoHeat, our Micropolishing has two processes. The first process introduces our proprietary cutting solution into the media. The cutting solution very slowly removes material off the part from the gentle wiping of our non-abrasive media. Different mixtures of solution and/or varying the length of the cutting process, greatly determines how much material is removed with an accuracy of 0.00001 of an inch. The second process is the polishing itself that utilizes a different type of proprietary solution. This solution acts as a varnish that makes the metal part look like it has a chrome finish. Most importantly, the finish has a Roughness Average (RA) of 2 or less, this allows for almost zero friction and resistance. The CryoHeat Micropolishing adds horsepower gains, achieving higher RPMs while simultaneously lowering operating temperatures and adding longer service life.

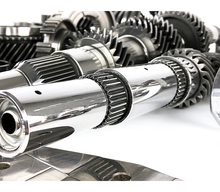

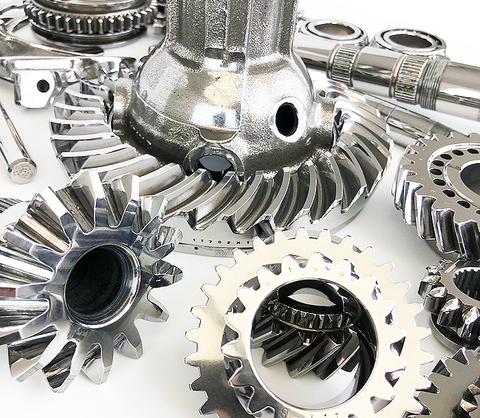

How Micropolishing & Deburring Will Help

The CryoHeat Micropolishing Process produces a surface that has several key advantages over other “superfinishing” techniques or un-finished surfaces.